There are four broad types of automatic fire sprinkler alarm valves used for automatic fire sprinkler systems. These include;

- residential fire sprinkler system alarm valve;

- wet pipe fire sprinkler system alarm valve;

- a deluge (dry pipe) fire sprinkler system;

- a pre-action fire sprinkler system.

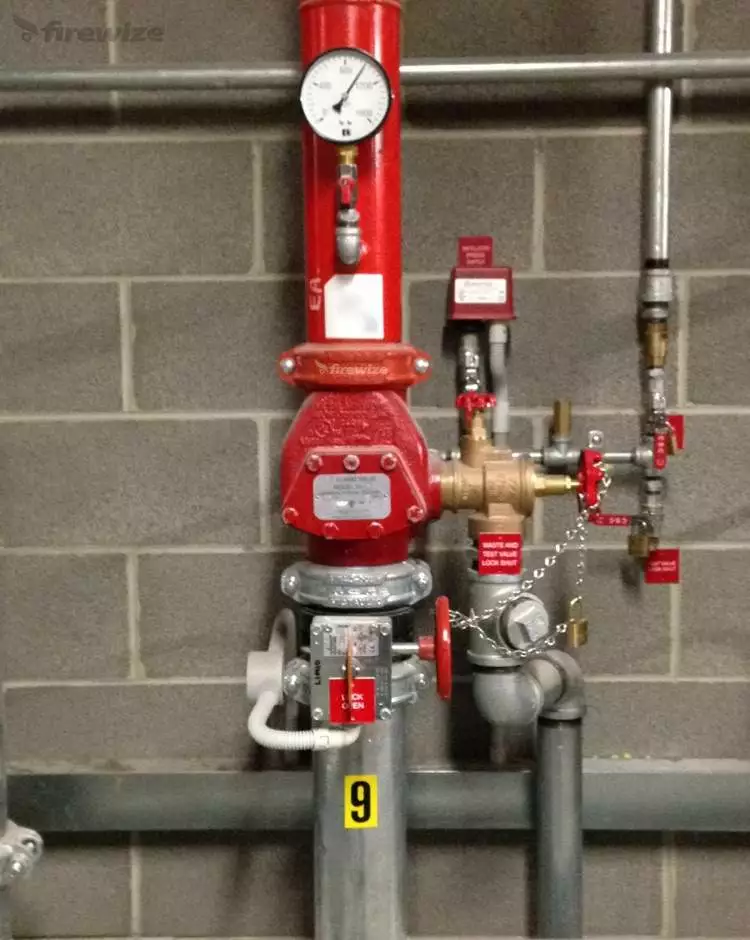

This document covers the information needed for a wet pipe automatic fire sprinkler system.

Reasons to replace a wet pipe sprinkler alarm valve

There are numerous reasons to replace an automatic fire sprinkler system alarm valve such as;

- deterioration due to age;

- unavailability of spare parts;

- damage or component failure;

- corrosion.

Under normal circumstances, a sprinkler alarm valve could last 50 years or more with only periodic maintenance required, as outlined in Australian Standard AS 1851 or by the manufacturer.

There are also replaceable components within an automatic fire sprinkler alarm valve such as gaskets that must be replaced periodically in order for the system operate reliably.