For routine servicing, this is important because AS 1851 provides a methodology for undertaking the routine servicing but typically does not set out the performance requirement, while AS2419 provides the Standard of performance for subsequent comparison.

Prior to conducting the routine (yearly) flow test or (five-yearly) hydrostatic pressure test, a person conducting the routine service will require specific performance details for the original installation.

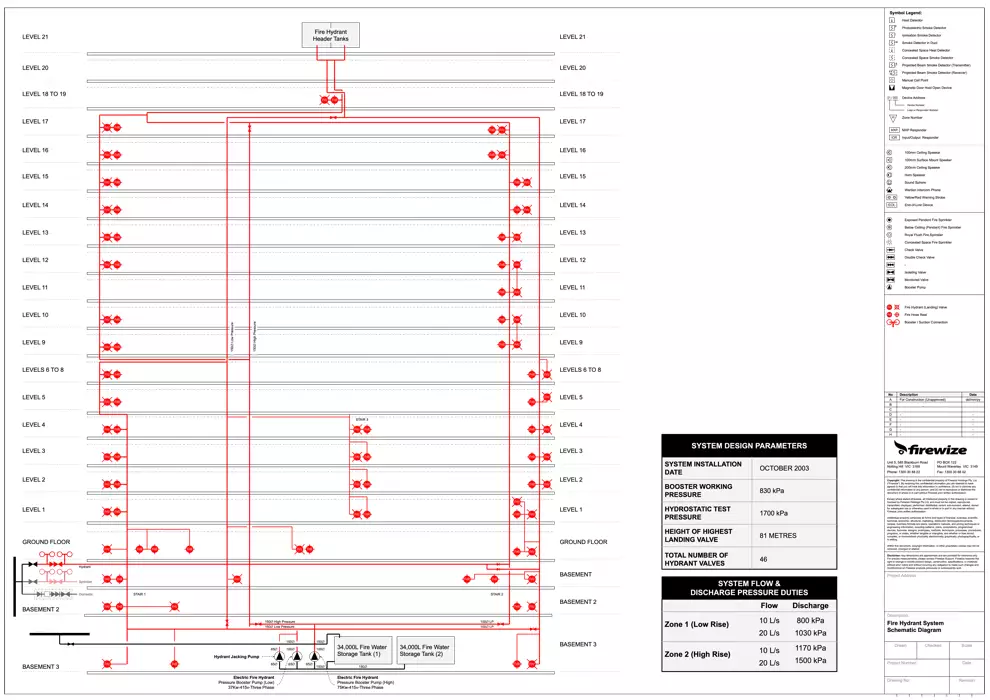

For a fire hydrant system this information typically includes the following data which can be found on the block plan, commissioning documentation, operation and maintenance manuals;

- Height of the highest fire hydrant landing valve above the booster;

- Standard of Performance for the system design (i.e. AS 2419.1:2005)

- System Hydrostatic Test Pressure (i.e. 1700 kPa)

- System Flow & Discharge Duties (i.e. 20 L/s at 1030 kPa)

- Installation Contractors Name

- Installation Date (DD/MM/YYYY)

- Total number (quantity) of hydrant landing valves

Of particular importance here are items 2, 3 and 4 as they provide the baseline for comparison for subsequent tests set out in AS1851.

This is not a exhaustive explanation of the relationship between the System Design, Installation and Commissioning Standard for Fire Hydrant Systems and the Routine Servicing of Fire Hydrant Systems but it does provide a basic framework for people to understand the relationship between the two Standards.